The cost of opening a set of injection molds may cost tens of thousands to hundreds of thousands of dollars. When the product style is large and the quantity is small, can we directly use 3D printing?

Simply to say, 3D printing is a prototyping process, while injection molding is a mass production process. If you want to create a unique product, you can choose 3D printing. However, if mass production is required, you need to choose injection molding.

The differences between 3D and injection molding.

1. The manufacturing principle is different.

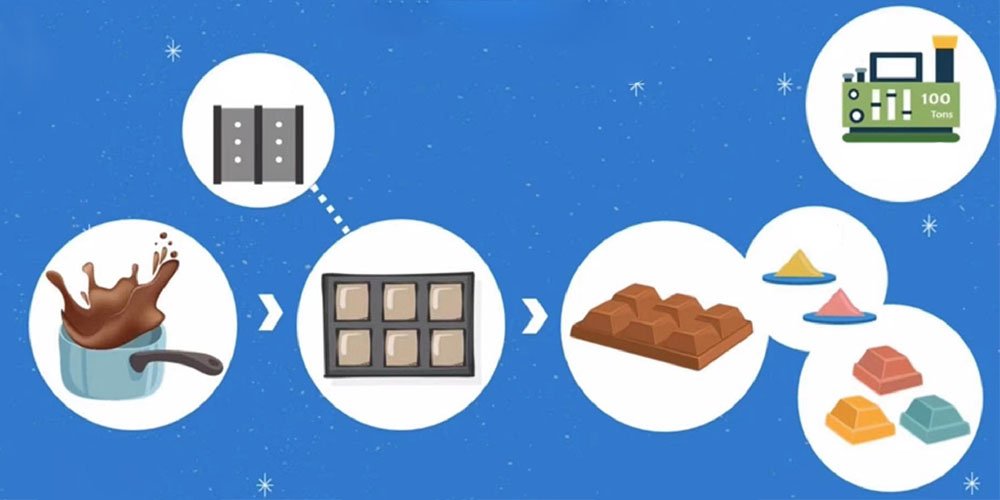

The principle of injection molding is just like making chocolate, the raw material is heated and melted first, then poured into the model, cooled and then demolded, and the product comes out, you can also add different colors to the material to make different colors of chocolate.

The biggest difference of 3D is that it doesn’t need exclusive molds, just like stacking blocks, from layer to layer. Because there is no mold mechanism, so the freedom is very large, you can make any shape of products, for example, 3D printing can make a hollow product. But injection molding can not do.

2. Different production efficiency

Although 3D printing can save the cost of molds, but the ability to quantify the production is much lower than injection molding production. For example, for a product the size of a pencil holder, 3D printing takes at least 2 hours, but plastic injection molding takes only 2 minutes.

3. Different appearance and detail

Because 3D printing is done in layers, the surface of the product will have a fabric-like texture. But injection molding can make specific texture or very smooth surface.

4. Structural strength is different

Injection molded products are usually more resistant to drop and impact due to the tighter bonding of the plastic, while 3D proofing is more fragile.

5. Cost difference

The initial development cost of injection molding is higher for grinding tools, but lower for raw materials and molding costs. However, 3D printing is a one-time customization cost. A product may cost several thousand dollars to tens of thousands of dollars.

Conclusion: According to the above 5 points, as to what method is more appropriate, you need to consider the functional needs of the product and the number of production to decide. With the current technology of 3D printing, it is not able to replace the quantitative ability of injection molding production, so the shell of the 3D printer on the market now, is also injection molding production. However, if you need a small amount of finished products or need to verify the product design, 3D printing is a good choice.

2 Responses

Definitely believe that which you said. Your favorite justification appeared to be on the net the simplest thing to be aware of. I say to you, I certainly get annoyed while people consider worries that they just do not know about. You managed to hit the nail upon the top and defined out the whole thing without having side-effects , people can take a signal. Will probably be back to get more. Thanks Gloriana Arvy Lundeen

Thanks for your comments.