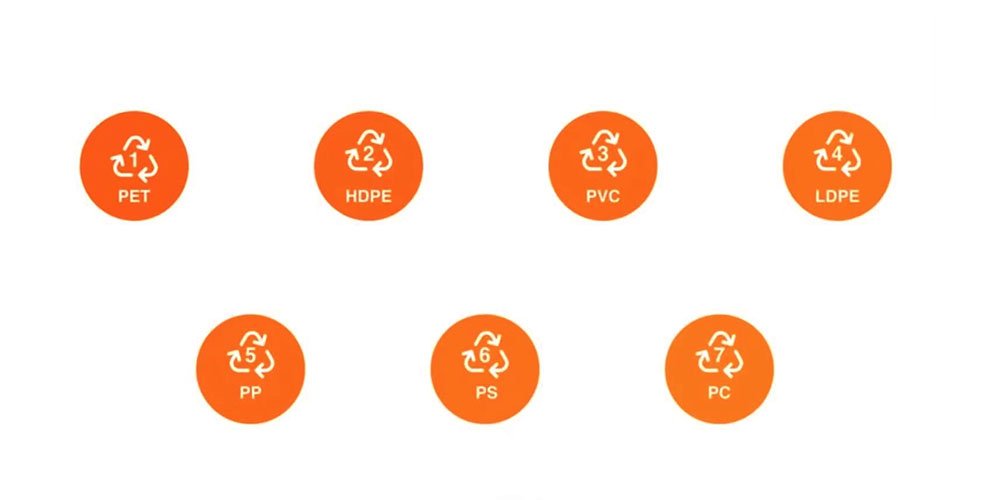

Seven Classes Of Plastics

NO.1 Plastics: PET ( Polyethylene Terephthalate)

- PET is commonly used in: mineral water bottles, carbonated beverage bottles, etc.

- Use: Heat-resistant to 65 ℃, cold-resistant to -20 ℃, only for warm drinks or frozen products, loaded with high-temperature liquids or heating is easy to deform, there are harmful substances melted out of the human body. And, No. 1 plastic products after 10 months of use, may release carcinogenic substances DEHP, toxic to testicles.

- Therefore, drink bottles and others used up after throwing away, do not use again as a cup of water, or used for storage for other items, so as not to cause health problems.

- Attention: Do not recycle beverage bottles to fill hot water, can not be placed in the car in the sun; do not fill wine, oil, and other substances.

No.2 Plastics: HDPE(High Density Polyethylene)

- HDPE is often used in: packaging for cleaning products and bath products

- Use: Can be reused after careful cleaning, but these containers are usually not good for cleaning, residual causes of cleaning supplies.It is best not to recycle, do not use again as a water cup, or used as a storage container for other items.

- Attention: It is difficult to clean thoroughly, it is recommended not to recycle.

No.3 Plastics: PVC(Polyvinyl chloride)

- PVC is commonly used in: raincoats, building materials, plastic film, plastic boxes, etc.

- Use: This material has excellent plasticity and cheap price, so it is commonly used. It can only be heat resistant to 80℃, and high temperature is easy to produce toxic substances, and even release toxic substances in the process of manufacturing. If it enters the body with food, it may cause breast cancer, birth defects in newborns and other diseases. Containers of this material may be less often used for packaging food. If used, never expose it to heat. Difficult to clean easy residue, do not recycle. Do not buy if filled with drinks.

- Attention: Not to be used for packaging of food products.

No.4 Plastics: LDPE(Low Density Polyethylene)

- LDPE is commonly used in: cling film, plastic film, etc.

- Use: Heat resistance is not strong, usually qualified PE cling film will be hot melt phenomenon when encountering temperature over 110℃, which will leave some plastic agents that human body cannot decompose. The grease in the food can also easily dissolve the harmful substances in the cling film.

- Tips: Therefore, food into the microwave oven, first remove the wrapped cling film. When high temperature products harmful substances, toxic substances with food into the body, may cause breast cancer, newborn babies congenital defects and other diseases.

- Attention: When heating in the microwave oven, do not wrap the food with plastic wrap.

No.5 Plastics: PP(Polypropylene)

- PP is commonly used in: soy milk bottles, yogurt bottles, juice drink bottles, microwave lunch boxes.

- Use: It is the only plastic box that can be safely put into the microwave oven (melting point up to 167 ℃), can be carefully cleaned and reused, need to pay special attention to some microwave lunch boxes, the box is indeed made of No. 5 PP (microwave oven special PP high temperature resistance of 120 ℃, low temperature resistance -20 ℃)

- However, because of the high cost, the lid is generally not made of special PP but made of No. 1 PET, because PET can not withstand high temperatures, so it can not be put into the microwave along with the box. To be on the safe side, take off the lid before putting the container into the microwave oven.

- Attention: When you put it into the microwave oven, put the lid down.

No.6 Plastics: PS(Polystyrene)

- PS commonly used in: bowl of noodles box, fast food box.

- Use: heat and cold resistant, but can not be put into the microwave oven, so as not to release chemicals due to high temperature (temperature resistance of 70 ℃ is released), and can not be used to load strong acid (such as orange juice), strong alkaline substances, because it will be decomposed for the human body is not good polystyrene, easy to cause cancer. Therefore, you should try to avoid using fast food containers to pack very hot food.

- Attention: Don’t use microwave oven to cook instant noodles in a bowl.

No.7 Plastics: PC(Polycarbonate)

- PC other classes are commonly used in: water bottles, water cups, milk bottles.

- Use: A material that is used in large quantities, especially in milk bottles, and is controversial because it contains BPA. In theory, as long as the process of making PC, BPA is 100% transformed into plastic structure, it means that the product is completely free of BPA, not to mention the release of BPA.

- However, if a small amount of BPA is not transformed into the plastic structure of PC, it may be released and enter the food or beverage. Therefore, be careful and pay extra attention when using this plastic container.

Plastic Molding Process

1. Injection Molding

- It is done by injection molding machine, the input cost is higher, the mold price is more expensive, the product price is very cheap, the market is more transparent, mainly suitable for small size products, the monthly output is very large, the mold and the product belong to very high precision.

- Appearance: solid core body when injection molding, the surface of the injection parts is shiny. Because there is an injection port, so the product after molding will have a small piece of unwanted part, a process will cut it off, although it is not obvious, if you look carefully or will find.

2. Blowing Molding

- Blowing molds are relatively simple, using air to blow out the shape of the product. The price of the mold is moderate, mainly suitable for making hollow class, packaging class and other special products, the monthly output is only a few thousand sets, and the field of use is limited.

- Appearance: Blow molding is empty core body, and the surface of blow molding is not easy to be flat.

3. Rotaional Moulding

- Rotational moulding is a large product in which plastic pellets are heated inside a mould and then the mould is rolled continuously to make the plastic bond with the inner wall of the mould. The mold is cheap, but the product is expensive, mainly used to make hollow type, packaging type, super large products.

- Appearance: The surface of rotomolding is also uneven, and there is no blowing mouth for rotomolding. The biggest feature of rotomolded products is that there is no seam, no injection port, the size shrinkage ratio is relatively large, and there are burr edges that need to be cut.

Properties Of Plastics

- Good corrosion resistance.

- Good balance of hardness, impulse, and resistance.

- Non-fading and moisture resistant.

- Easy to color.

- Lighter weight.

- Low cost.

Application Of Plastics

- Medical equipment

- Chemical containers

- Sporting goods

- Kitchen supplies

- Household products

- Handbags

- Teaching aids/toys

- Automobile fuel tank

- Cable Insulation

- Furniture